Shandong Youyue, founded in 1995 and headquartered in Linyi, Shandong, is a leading domestic wet wipes manufacturer. Upholding the core values of “integrity as the foundation, quality first, innovation-driven, and customer-centric,” the company is committed to becoming a global provider of wet wipes product solutions.

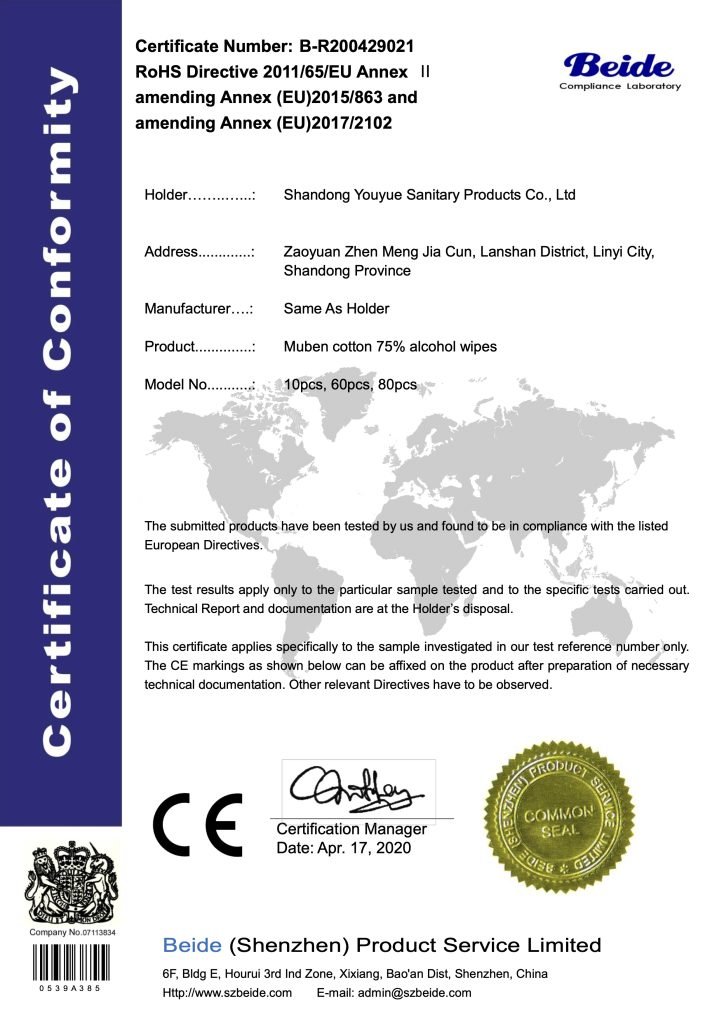

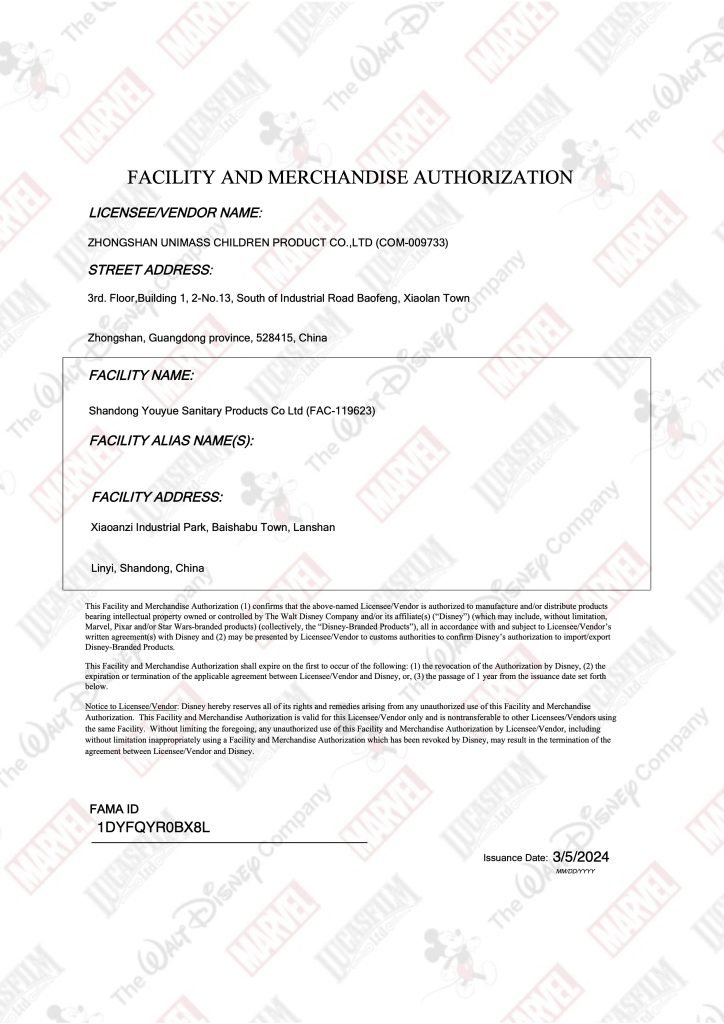

After nearly three decades of development, the company has become one of the top three wet wipes manufacturers in China, with annual sales exceeding RMB 1 billion. Its products are exported to over 10 countries and regions worldwide. The company holds multiple authoritative certifications, including ISO 9001 Quality Management System, ISO 14001 Environmental Management System, and BSCI Business Social Compliance Initiative certification, and has established a comprehensive quality control system spanning from raw material inspection to finished product delivery.

The company places a strong emphasis on innovation and R&D, holding more than 20 patented technologies and pioneering the launch of a biodegradable wet wipes series. Through continuous product upgrades and technological innovation, it provides consumers with safe, convenient, and eco-friendly cleaning experiences, gaining wide recognition across various fields such as medical, maternal-infant, and household care.

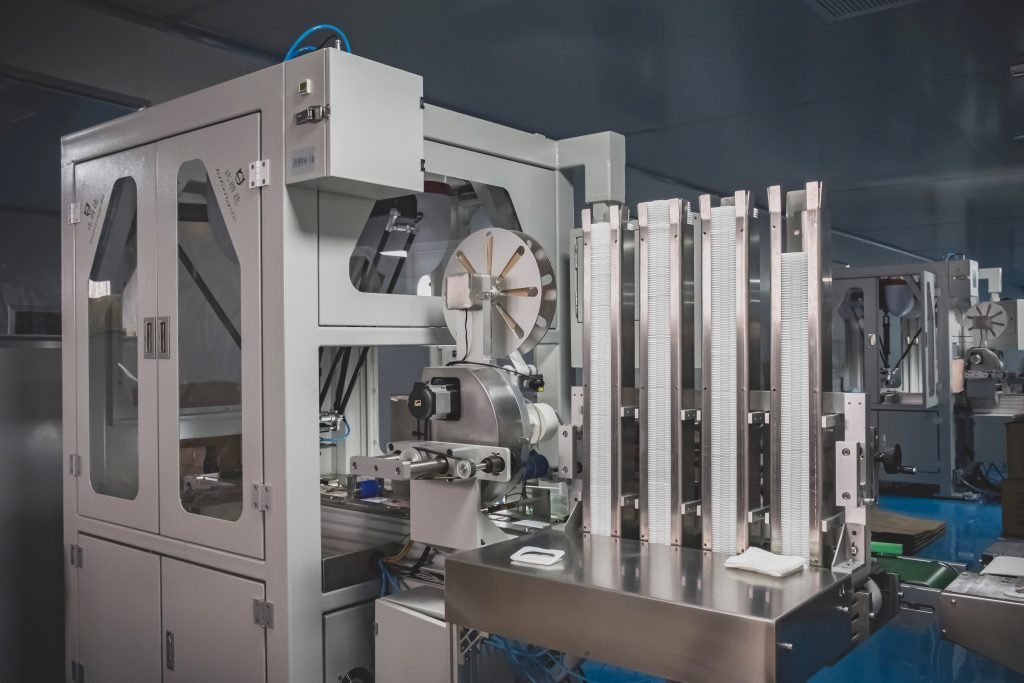

With its professional team, advanced facilities, and well-established management system, Shandong Youyue is steadily advancing toward its vision of “safeguarding the cleanliness and health of every household and leading the industry toward sustainable development.”

The company has established a comprehensive four-level quality control system spanning “incoming materials – production process – finished product outgoing,” ensuring product safety and consistent quality through stringent standards. The Incoming Quality Control (IQC) implements full-item testing, screening 18 indicators including basis weight, microbiology, and heavy metals for plant fibers, functional liquids, packaging materials, and biodegradable raw materials, preventing non-conforming items from entering the production line at the source.

The In-Process Quality Control (IPQC) conducts hourly inspections and sampling, providing real-time monitoring of four critical nodes: composite forming, cutting and folding, packaging, and sterilization. This ensures core process parameters meet standards, such as moisture uniformity deviation ≤ ±5%, dimensional accuracy error ≤ ±1mm, and seal peel strength ≥ 30N/15mm.

The In-Process Quality Control (IPQC) conducts hourly inspections and sampling, providing real-time monitoring of four critical nodes: composite forming, cutting and folding, packaging, and sterilization. This ensures core process parameters meet standards, such as moisture uniformity deviation ≤ ±5%, dimensional accuracy error ≤ ±1mm, and seal peel strength ≥ 30N/15mm.

The In-Process Quality Control (IPQC) conducts hourly inspections and sampling, providing real-time monitoring of four critical nodes: composite forming, cutting and folding, packaging, and sterilization. This ensures core process parameters meet standards, such as moisture uniformity deviation ≤ ±5%, dimensional accuracy error ≤ ±1mm, and seal peel strength ≥ 30N/15mm.

The company has built its innovation system around four key dimensions: Product, Green Initiatives, Management, and Business Models.

Driven by user scenarios, it leverages technologies like ±5% high-precision liquid dispensing, differentiated fiber applications (e.g., 0.1D microfiber), and 20+ patents to create product performance advantages.

It leads in developing bio-based biodegradable wipes, certified to U.S. IWSFG and EU EN13432 standards, while fully implementing recyclable packaging and plant-based ingredient substitutions.

By adopting Industrial Internet systems, it achieves full-chain digital management for precise cost reduction and efficiency gains.

It pioneered the synergistic “roll goods + finished products + proprietary brand” model, with its own brand ranking among the top in its category during major e-commerce promotions.

We drive industry transformation through a full lifecycle green system covering products, manufacturing, and supply chain.

The company leads in the development of PLA bio-based biodegradable wet wipes, certified to U.S. IWSFG and EU EN13432 standards, achieving complete degradation within 180 days, with annual sales exceeding 800 million pieces. Over 80% of all product lines utilize natural ingredients**, and packaging is designed for lightweight and recyclability.

All three of its production bases are recognized as “Provincial Green and Low-Carbon Factories.” Through energy-saving technological upgrades, the company saves over 8 million kilowatt-hours of electricity annually, reducing carbon emissions by 6,400 tons. Industrial water reuse efficiency reaches 90%, and a closed-loop wastewater treatment system has been established.

A green supplier evaluation system has been implemented, with 100% of raw materials certified for sustainable sourcing. A low-carbon logistics network reduces transportation carbon emissions by over 800 tons annually.

The company has cumulatively invested over RMB 5 million in public welfare funds, supporting more than 500 rural schools. A comprehensive employee career development system is in place, with senior skilled technicians constituting 25% of the workforce. It actively participates in formulating national and industry standards, promoting green development across the sector.

Partner with a manufacturer that prioritizes quality, hygiene, and sustainability.